- 877-447-5956

- INFO@VIACLEANTECHNOLOGIES.COM

INDUSTRIES

Healthcare

Provide a new standard of clean for your patients and employees when your healthcare facility is BIOPROTECTED™.

The BIOPROTECTUs™ System of products will complement your current cleaning protocol and provide an increased assurance of clean weather in an operating room or hospital room, cafeteria or reception area. A List N Disinfectant can be used to treat beds, equipment, linens and curtains where microbes might grow if these surfaces are not correctly cleaned.

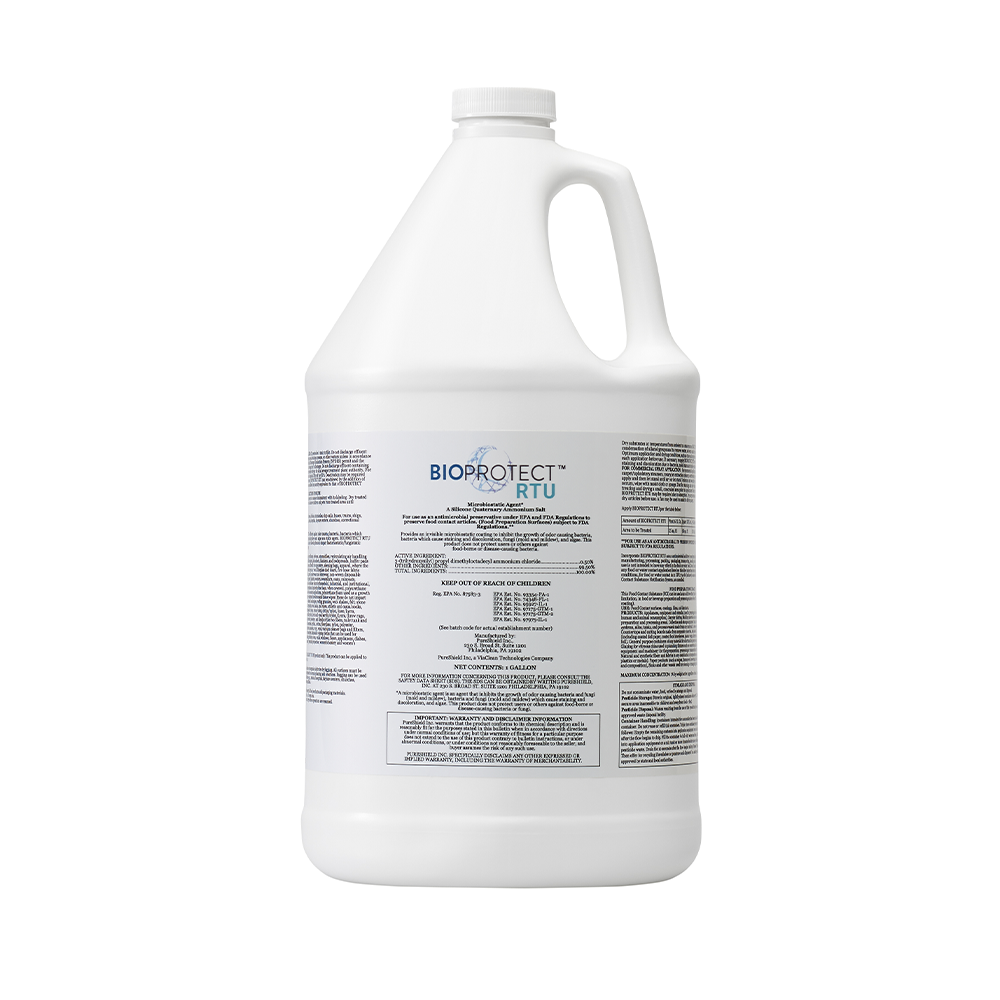

The BIOPROTECTUs™ System uses patented, registered technologies: a List N disinfectant to disinfect surfaces against viruses, bacteria, and germs, and BIOPROTECT™ RTU antimicrobial surface protectant, to keep surfaces free of odor- and stain-causing bacteria, fungi (mold and mildew), and algae between cleanings, for up to 90 days (3 months). Additional products offered from ViaClean include the registered BIOPROTECT™ 500 concentrate and FDA-registered BIOPROTECT™ Hydrating Hand Sanitizer.

Recommended products for healthcare facilities such as hospitals:

A VIACLEAN TECHNOLOGIES PRODUCT

Helpful Links

Contact Info

- 230 S Broad Street Suite #1201 Philadelphia, PA 19102

- 877-447-5956

- info@viacleantechnologies.com